Field Service & Asset Management

Revolutionize your Field Service and production with the Innomize's AI solution: Maximize uptime - and get an overview in Real-Time.

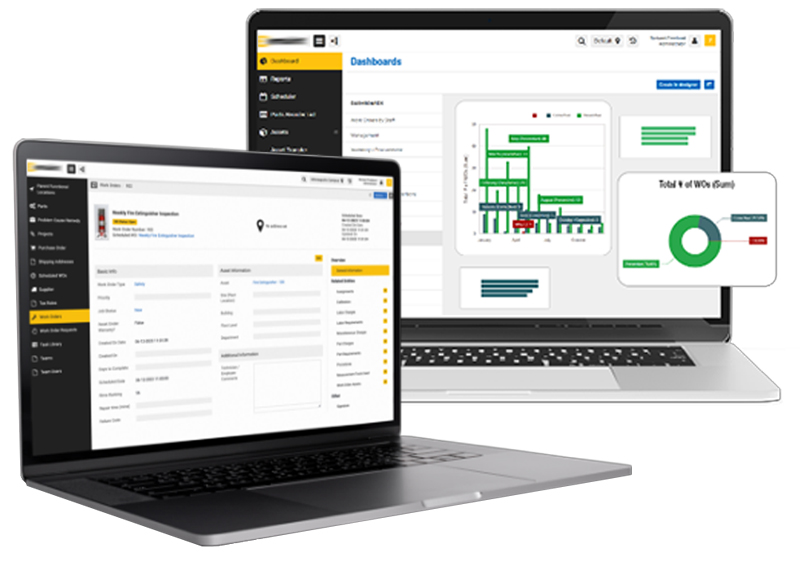

Innomize offers a revolutionary Field Service and Asset Management platform - and IIoT software that connects hardware and software in a cloud-based ecosystem. Our solution gives you full control, optimizes processes and ensures satisfied customers by transforming targeted solutions for your customers with access to multiple languages.

A cloud-based ecosystem that gives you full control and optimizes your processes

Innomize offers a revolutionary Field Service / Asset Management platform - and IIoT software that connects hardware and software in a cloud-based ecosystem.

Our solution gives you full control, optimizes processes and ensures satisfied customers by transforming targeted solutions for your customers with access to multiple languages.

Why Innomize Field Service & Management System?

With Innomize you get more than just software – you get a strategic partner to optimize your maintenance processes and ensure maximum uptime.

- Full traceability: Track every asset from production to disposal and gain full control over your agreements.

- Predictive maintenance: Minimize downtime and avoid costly repairs with data-driven insights.

- Optimized processes: Automate routine tasks and free up time for more value-adding activities.

- Satisfied customers: Deliver fast and efficient service that exceeds customer expectations.

Innomize is a leading partner in creating fast and effective communication and knowledge sharing in Real Time.

When it comes to customer care, time-to-value and ROI – we help 375+ companies create fast and effective communication and knowledge sharing globally.

Benefits of the Field Service and Asset Management system

- Asset Life Optimization

Get detailed asset information, status, and maintenance history in a few clicks. Manage the lifecycle of your assets, from purchase to disposal, and extend their lifespan. - Multi-site management

Manage maintenance and standardize your strategy across workplaces, languages, and currencies. Simplify enterprise-level reporting and streamline audit compliance. - Software and hardware integration

Simplified workflows and seamless data sharing with 1000+ apps. Connect to sensors, leverage data from SCADA and PLC systems, and integrate with ERP and BI platforms.

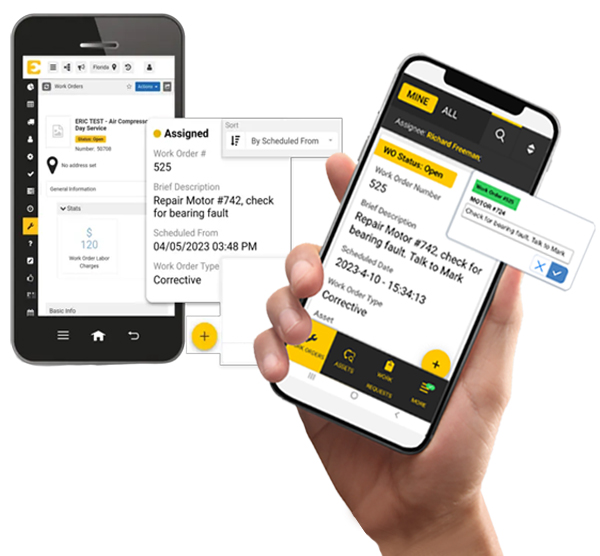

Mobile Work Orders: Flexibility in the Field

Lack of information and neglected teams lead to maintenance nightmares – and that’s where our platform comes in. Innomize connects teams and breaks down barriers to industrial data, maximizing uptime and reliability.

- Work offline

Simplifies working offline, in the field or on the factory floor. - Ultimate configurability

Customize forms, fields, display, and more to your specific needs.

Easily manage work orders on the go

Manage, edit, and assign work orders in the field. Build work orders from your desktop and send them to your team on the factory floor. Receive push notifications for important updates and track your work with a few taps to ensure your team is never left behind.

Optimize your workflow

- Add photos and videos

Quickly and easily add photos and videos to your work orders. - Inspection lists

Design PM checklists and routine inspections where staff check off tasks as they go. - Document management

View and upload important documents directly from the field. - Integrated process

Do it all, from work requests to ordering parts. Scan asset QR codes to submit a work request to inspect faulty equipment. Book parts for jobs, streamlined by Innomize ERP integration. - Tracking and signatures

Track work hours and require digital signatures for work order completion.

Take the helm of your asset command center

Find a failed asset or critical part with a quick search. Explore your asset details and recent maintenance history. Attach assets to work orders and view other open work orders for nearby assets when you’re already in the field. Collect data in the field with select sensors and boxes and create your own tool integration.

Searchable, flexible spare parts inventory

Quickly find the parts you need. See recommended parts for specific assets and rely on an AI parts reorder list to optimize inventory levels. Get a view of what’s in stock, both in the warehouse and across your global organization, and request critical parts from across your entire site.

Scan and send work requests

Found a faulty motor? Scan QR codes for work requests or barcodes for asset details. When walking around the facility, users can scan barcodes to view asset or part details and history. And any staff can scan a QR code on problematic assets to submit a work request.

Get started with the new and innovative solution - with the remote support system, we transform the way you work with support.

Innomize and OEE: A Strong Connection

One of the most effective ways to measure success is by focusing on OEE (Overall Equipment Effectiveness). OEE is a key performance indicator that quantifies how efficiently a production facility is being utilized. It takes into account three main factors:

- Availability

What percentage of the planned production time the equipment is actually in operation. This is affected by breakdowns, repairs and conversions. - Performance

How fast the equipment is running compared to its maximum speed. This is affected by small stops, idling, and reduced speed. - Quality

What percentage of the goods produced are defect-free. This is affected by scrapping and rework.

Innomize systems can directly contribute to improving all three components of OEE:

- Forbedret Tilgængelighed

By implementing proactive maintenance, such as preventive and predictive maintenance, we can reduce unplanned downtime and extend the life of critical components. The systems can also track spare parts and plan maintenance activities more effectively. - Improved Accessibility

We can help identify bottlenecks and inefficiencies in the production process. By analyzing data from the equipment, you can optimize operating conditions and ensure that machines are running at the most efficient speed. - Higher Quality

Through regular calibration and maintenance of equipment, we can minimize defects and ensure consistent product quality. Error tracking and root cause analysis can also lead to long-term improvements.

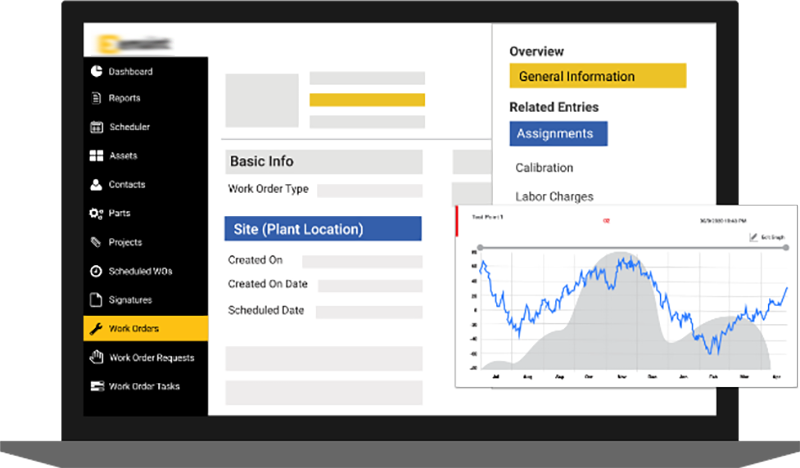

How our sensors and software deliver on the promise of connected reliability

Condition monitoring

Vibration sensors send data to the cloud, where the data is accessed by Innomize condition monitoring – the companion condition monitoring allows users to view recent measurements and analyze historical data.

Maintenance personnel can view overall vibration readings, time waveform readings, or FFT graphs where signal components are seen in a condition monitor – the solution also includes advanced vibration analysis capabilities for experts and an AI diagnostic tool for non-experts that provides recommendations, depending on the software package.

Field service & Asset Management solution

Our platform is a maintenance and reliability software for managing work orders, PMs, assets, parts inventory, KPI reporting and more. The solution connects to condition monitoring – giving MRO teams vital asset data and the power to automate work orders based on machine condition.

What does it mean? A sensor detects a fault, and condition monitoring sends vibration alerts to the platform. The solution automatically generates a work order to start the process of verifying what’s wrong and fixing the machine. You can also send specific narrowband alerts that trigger fault-specific work orders. Going forward, teams can view maintenance and vibration history to gain insight into asset health and optimize maintenance strategy.

Contact us for more information about Field Service and Asset Management solutions!

Contact us by phone +45 40 86 34 00 or by email info@innomize.dk